The Wheatstone Bridge is a fundamental electrical circuit used to measure unknown resistances with high precision. Invented by Samuel Hunter Christie in 1833 and later popularized by Samuel Wheatstone in 1843, this device has become a cornerstone in electrical engineering and instrumentation. The Wheatstone Bridge operates on the principle of balancing two legs of a circuit, allowing for accurate measurements of resistance. This article aims to provide a comprehensive understanding of the Wheatstone Bridge, including its construction, working principle, applications, advantages, and limitations.

Historical Background

The Wheatstone Bridge emerged during a period of rapid advancement in the study of electricity and magnetism. Samuel Hunter Christie first described the bridge in his work on electrical resistance, but it was Wheatstone who refined the design and demonstrated its practical applications. The bridge quickly gained popularity in laboratories and industries for its ability to measure resistance accurately.

The Wheatstone Bridge’s significance grew with the development of electrical engineering as a discipline. It became a standard tool for calibrating measuring instruments and testing electrical components. Over the years, various modifications and improvements have been made to the original design, leading to the development of modern variants that incorporate digital technology and automated measurement systems.

Construction of the Wheatstone Bridge

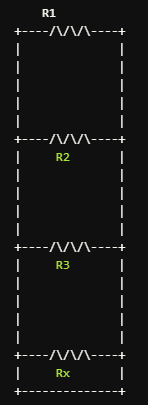

The Wheatstone Bridge consists of four resistors arranged in a diamond shape, with a voltage source and a galvanometer connected across the bridge. The basic configuration includes:

1. Resistors: Four resistors are arranged in two pairs. The resistors ![]() and

and ![]() form one leg of the bridge, while

form one leg of the bridge, while ![]() and

and ![]() (the unknown resistor) form the other leg. The resistors can be of known values or adjustable.

(the unknown resistor) form the other leg. The resistors can be of known values or adjustable.

2. Voltage Source: A DC voltage source is connected across the bridge to provide the necessary current for measurement.

3. Galvanometer: A sensitive galvanometer is connected between the junctions of the two pairs of resistors. The galvanometer detects the current flowing through it, indicating whether the bridge is balanced.

4. Adjustable Resistor: Often, one of the resistors (usually ![]() ) is adjustable, allowing for fine-tuning to achieve balance.

) is adjustable, allowing for fine-tuning to achieve balance.

The basic schematic of a Wheatstone Bridge can be represented as follows:

Working Principle of the Wheatstone Bridge

The operation of the Wheatstone Bridge is based on the principle of null detection, which states that when the bridge is balanced, the potential difference between the two midpoints (where the galvanometer is connected) is zero. The steps involved in the working principle are as follows:

1. Balancing the Bridge: Initially, the bridge is unbalanced, and a current flows through the galvanometer. By adjusting the known resistors ![]() and

and ![]() , the user can manipulate the circuit until the galvanometer reads zero, indicating that no current flows through it.

, the user can manipulate the circuit until the galvanometer reads zero, indicating that no current flows through it.

2. Condition for Balance: The bridge is said to be balanced when the ratio of the resistances in one leg is equal to the ratio in the other leg. Mathematically, this condition can be expressed as:

![]()

Rearranging this equation allows for the calculation of the unknown resistance ![]() :

:

![]()

3. Measurement: Once the bridge is balanced, the value of the unknown resistor can be accurately determined using the known values of ![]() ,

, ![]() , and

, and ![]() . This method provides a high degree of accuracy compared to direct measurement techniques.

. This method provides a high degree of accuracy compared to direct measurement techniques.

Applications of the Wheatstone Bridge

The Wheatstone Bridge has a wide range of applications across various fields, including:

1. Resistance Measurement: The primary application of the Wheatstone Bridge is to measure unknown resistances with high precision. It is widely used in laboratories and industrial settings for calibrating measuring instruments.

2. Material Testing: The bridge is employed in material testing to determine the resistivity of materials. By measuring the resistance of a sample, engineers can assess its electrical properties and suitability for specific applications.

3. Temperature Measurement: The Wheatstone Bridge is used in conjunction with temperature sensors, such as thermistors and RTDs (Resistance Temperature Detectors), to measure temperature changes accurately. The resistance of these sensors varies with temperature, allowing for precise temperature readings.

4. Strain Gauges: In structural engineering, the Wheatstone Bridge is used with strain gauges to measure deformation in materials. The change in resistance of the strain gauge due to applied stress can be accurately measured using the bridge configuration.

5. Calibration of Instruments: The Wheatstone Bridge is utilized to calibrate various electrical instruments, ensuring their accuracy and reliability in measurements.

Advantages of the Wheatstone Bridge

The Wheatstone Bridge offers several advantages that contribute to its widespread use:

1. High Accuracy: The bridge provides highly accurate measurements of resistance, making it suitable for laboratory and industrial applications.

2. Null Measurement: The null detection method eliminates the influence of external factors, such as temperature variations and voltage fluctuations, leading to more reliable results.

3. Versatility: The Wheatstone Bridge can be adapted for various applications, including resistance measurement, temperature sensing, and strain measurement.

4. Simplicity: The basic design of the Wheatstone Bridge is straightforward, making it easy to set up and use, even for those with limited experience in electrical measurements.

Limitations of the Wheatstone Bridge

Despite its advantages, the Wheatstone Bridge has certain limitations:

1. Requires Calibration: The accuracy of the Wheatstone Bridge depends on the precision of the known resistors used in the circuit. Regular calibration is necessary to maintain measurement accuracy.

2. Limited to DC Circuits: The traditional Wheatstone Bridge is primarily designed for direct current (DC) applications. While there are AC variants, they require additional considerations and modifications.

3. Sensitivity to Temperature: The resistance of the components used in the bridge can change with temperature, potentially affecting measurement accuracy. Care must be taken to minimize temperature variations during measurements.

4. Complex Configurations: For complex circuits with multiple unknown resistances, the Wheatstone Bridge may become cumbersome, requiring more advanced techniques for accurate measurement.

Conclusion

The Wheatstone Bridge is a fundamental tool in electrical engineering and instrumentation, providing a reliable method for measuring unknown resistances with high precision. Its historical significance, construction, working principle, and wide range of applications underscore its importance in both theoretical and practical contexts. Despite its limitations, the Wheatstone Bridge remains a cornerstone of electrical measurement techniques, and its principles continue to influence modern instrumentation and engineering practices. Understanding the Wheatstone Bridge not only enhances our knowledge of electrical circuits but also highlights the enduring relevance of classical methods in the ever-evolving field of technology.